| Item |

Test

condition |

Unit |

ZrO2 |

99%

Al2O3 |

95%

AL2O3 |

75%

AL2O3 |

Mullite

(3Al2O3'2SiO2) |

Steatite (MgO'SiO2) |

Cordierites (SiO2'Al2O3'MgO) |

SiC (Silicon Carbide) |

Si3N4 (Silicon Nitride) |

| Color; Appearance |

|

|

White; dense |

White; dense |

White, red orblack; dense |

White or yellow ; Porous |

Dark Brown; Dense |

White,yellow; Dense |

White; Dense |

Black; Dense |

Black; Dense |

| Bulk Density |

Archimede |

g/cm3 |

6.00 |

3.80 |

3.74 |

3.6 |

3.2 |

2.7 |

2.6 |

3.2 |

3.2 |

| Water Absorption |

|

% |

0 |

0 |

0 |

0.6 |

0 |

0 |

0 |

0 |

0 |

| Mechannical Characteristics |

Vickers hardness |

Loaded 4.9 |

Gpa |

13.2 |

15.2 |

15 |

9 |

10.8 |

5.8 |

7.2 |

22 |

13.9 |

| Flexural strength |

Crooked distance 80mm |

Mpa |

1000 |

310 |

345 |

120 |

280 |

190 |

150 |

540 |

610 |

| Compressive Strengh |

|

Mpa |

5690 |

2150 |

_ |

_ |

_ |

_ |

_ |

_ |

3800 |

| Young's Modulus of Elasticity |

|

Gpa |

200 |

360 |

320 |

160 |

210 |

120 |

140 |

430 |

290 |

| Poisson's Ratio |

|

|

0.31 |

0.23 |

0.23 |

0.17 |

0.27 |

0.22 |

0.31 |

0.16 |

0.28 |

| Thermal Characteristics |

Coefficient Linear Thermal expansion |

20-500℃ |

1×10-6mm/℃ |

10.5 |

6.9 |

6.9 |

7.1 |

5 |

7 |

0.1 |

3.7 |

2.6 |

| 20-800℃ |

11 |

7.0-8.0 |

6.5-8.0 |

7.5 |

5.8 |

7.7 |

0.1 |

4.4 |

3.2 |

| Thermal conductivity |

20℃ |

W/(m.K) |

3 |

≥29 |

≥24 |

8 |

5 |

8 |

4 |

60 |

20 |

| Thermal shock resistance |

℃ |

_ |

300 |

200 |

200 |

320 |

_ |

_ |

_ |

400 |

550 |

Elec- Characteristics

|

Dielectric strength |

|

KV/mm |

11x106 |

15 |

14 |

12 |

15 |

18 |

19 |

_ |

10 |

| Bulk Resistivity |

20℃ |

Ω.cm |

≥1013 |

≥1014 |

≥1014 |

≥1014 |

≥1014 |

≥1014 |

≥1014 |

≥105 |

≥1014 |

| 300℃ |

≥106 |

≥1011 |

≥1011 |

≥1010 |

≥1012 |

≥1010 |

≥1014 |

≥104 |

≥1012 |

| 500℃ |

≥103 |

≥109 |

≥109 |

≥108 |

≥108 |

≥107 |

≥1011 |

≥103 |

≥1010 |

| Dielectric constant |

1MHz |

|

33 |

9.8 |

9.4 |

8.4 |

7.4 |

6 |

4.8 |

_ |

_ |

| Loss factor |

|

10-4 |

520 |

20 |

38 |

1500 |

148 |

108 |

48 |

_ |

_ |

*The values are typical material properties and may vary according to products configuration and manufacturing process. For more details, please feel to contact us.

Advanced Technical Ceramic Plant

Application note

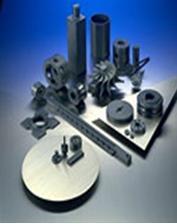

Alumina Ceramics (99%Al2O3---Cordierites)

Alumina ceramic is the most widely used material out of a variety of fine ceramics, it is also featured with the same crystal structure as sapphire and ruby after sintering process ( ). This material is applied to widely diversified industrial field for its superb material characteristics such as high electrical insulation, high mechanical strength, high wear and chemical resistance.

Suggested material for application

● Electrode Assembly or Insulator in BBQ Grill 95% Al2O3 / Steatite

● Lamp holder and base, electrode end insulator 95% Al2O3 / Steatite

● Mechanical Seal ring or Electron tube housing 95% Al2O3

● Valve Discs 95% Al2O3

● Hybrid IC Substrate 95% Al2O3

● Crucible, Nozzle, Sagger, heat corrosion and wear resistant parts 99 % Al2O3

● Semiconductor Processing Equipment parts Cordierite or 99.5% AL2O3

Silicon Nitride

Silicon nitride ( ) exceeds other materials in thermal shock resistance. This material does not deteriorate at high temperature, therefore it's appropriate for automotive engine and parts for gas turbine, including turbocharger rotor, glow plug of diesel engine and hot plug. It is expected that the field range this material can be applied to will widely expand. Silicon nitride ( ) exceeds other materials in thermal shock resistance. This material does not deteriorate at high temperature, therefore it's appropriate for automotive engine and parts for gas turbine, including turbocharger rotor, glow plug of diesel engine and hot plug. It is expected that the field range this material can be applied to will widely expand.

● Molten Metal Parts

● Gas Turbine Parts

Silicon Carbide

Silicon carbide maintains its high mechanical strength up to as high temperature as 1,400 . Typical application is part for mechanical seal ring and pump due to higher chemical corrosion resistance than other ceramics. Silicon carbide maintains its high mechanical strength up to as high temperature as 1,400 . Typical application is part for mechanical seal ring and pump due to higher chemical corrosion resistance than other ceramics.

● Mechanical Seal Ring

● High Temperature Resistance Parts

Zirconia Ceramics

Zirconia ceramic has high mechanical strength and toughness at room temperature out of a series of engineering fine ceramics. Zirconia was the first material adopted to fine ceramic scissors or knife application. Its excellent surface smoothness has brought this material into parts for pump products. Zirconia ceramic has high mechanical strength and toughness at room temperature out of a series of engineering fine ceramics. Zirconia was the first material adopted to fine ceramic scissors or knife application. Its excellent surface smoothness has brought this material into parts for pump products.

● Optic ZrO2 Ferrule

● Pump Parts, Knives

Work had for quality, Better service for customer, we have active developing vigor and vitality, strict manage system. We are looking forward for we could development and cooperate with yours.

Approval

|